I started out with a ton of things, including many that I did not even know how to use. It was amazing to have all the tools at my disposal from the start, thanks to a wonderful Christmas gift from my boyfriend. He had basically bought me a whole studio kit from Devardi and I could just dive right in. Not everyone can or wants to jump in that hard from the start, so I am going to let folks know what I use the most from my initial set up as well as the other things I have added on my journey.

One quick note about vendors before I go further. I use three main suppliers for my glass and tools. My favorite by far is Mountain Glass. The folks there are super nice and very helpful when it comes to helping you decide what it is you need. Their customer support is fantastic. They also ship very quickly, and while I have not yet done it myself, I understand that they also price match their competitors. I recommend signing up for their weekly emails as they always have great sales going. Plus sometimes they send you get cool weird things like posters, stickers or even a music CD in your packages. ;-)

Another supplier I use is Howaco Glass. This vendor has low prices on soft glass, and carries the major brands I love. She also allows you to purchase a single rod of a color. This is WONDERFUL for when you just want to test something out. Shipping is not super quick, but I have never had an issue with my orders and I love the prices and convenience of buying just a single rod.

Finally, I want to talk about Devardi. Sometimes if you mention that name on some of the glass forums, you will get some pretty harsh reactions. People either love or hate these products. Personally, I think their kits for starting out are pretty fantastic for those who want to jump right in with all the tools at a good price. Their marvers and mandrels are good quality and the price is fantastic. Their glass is usually the big point of contention with folks. It is "stiffer" than other "soft" glasses. This means it can sometimes take a little longer to melt and work. Personally, I was GLAD to have that extra time when I was just starting out. It saved me a lot of dripping drooping glass. There are some professional artisans that prefer this glass for certain things because the stiffness allows for some pretty cool sculptural work as well. I absolutely LOVE some of their colors (cobalt blue transparent, for example), and I have found others just are not to my taste (I find their clear clouds up and gets muddy with a hothead, and also is too stiff for encasing). My recommendation regarding glass is to learn the basics and then sample everything out there (all brands) and find what suits your style and budget. You cannot bead the price for bundles of Devardi glass to just get your feet wet and learn how to make beads.

Safety

Torch

Devardi propane torch with bracket

Devardi propane torch with bracket

Other torches need two fuels to work, usually propane or something similar, and oxygen. These torches start at a couple hundred dollars and run into the thousands. You also need a source of oxygen, either tanked oxygen (not legal everywhere), or an oxygen concentrator (which can be quite pricey, even for a refurbished one). I took a class once and it used a duel fuel torch and I made a hot mess of the glass straight off because the extra heat from the torch, plus a softer glass than I was used to, it just melted and dripped onto the table. I am more experienced now, am used to the softer glass, and itching to work faster, so at some point I might add this type of set up to my studio space (though I will not forsake my hothead).

Cooling

|

|

After you create your beads you will need some method of slowing the cooling process of the beads. If they cool too quickly they will experience thermal shock and crack. There are a number of ways to do this. I personally use a fiber blanket. After a great deal of use, they can start to shred, but my first one has lasted me over two years and I just recently bought a replacement for it.

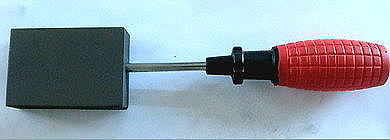

Because I often work in a very cold garage, I added an extra measure of insulation by building a little box/frame for my fibre blanket out of foil insulation (shown to the left) and duct tape. I think this helps hold the heat a little better. Other options for cooling are to use a container full of vermiculite or annealing bubbles. When your bead is done, and no longer glowing (you can check this by holding it briefly under your table where it is darker), you can plunge the mandrel into the pot. The vermiculite or bubbles will allow it to cool off more slowly and prevent cracking. Some people even go to goodwill and buy an old crock pot and put the vermiculite/bubbles in that and turn it on to help retain more heat. |

Annealing

Devardi also sells a Mini Annealer. Again, this item is a huge point of contention amongst long time glassworkers, as to whether it truly anneals or not. I have been using one for two years, and my beads take some pretty hefty abuse and they are holding up, but I am waiting to get the Caldera before I start selling any of my work. I am very happy with this little device and love that it has enabled me to really get use out of my creations thus far. The annealer can also be used as a rod warmer (which is something I will discuss a bit further down).

Mandrels and Bead Release

|

These are two items you absolutely must have to make beads. The mandrels are the metal wires on which you form the beads. The bead release is a runny goop you apply to the mandrels that will prevent the beads from sticking to the steel.

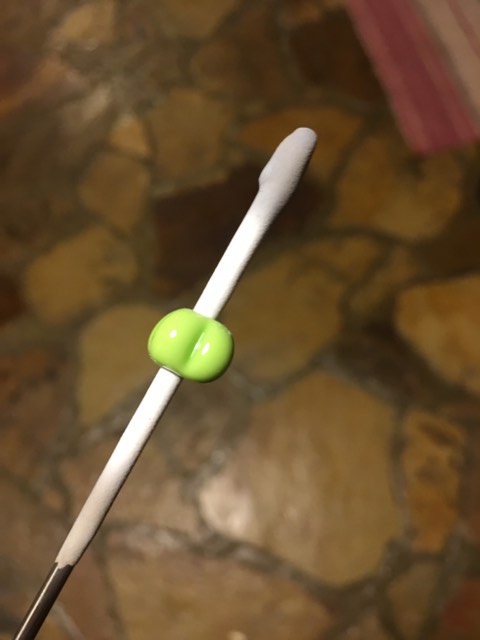

For mandrels, I buy mine from both Devardi and Mountain Glass. Devardi is a little cheaper but you need to take a bit of sand paper to the ends to smooth them, Mountain Glass has that already done. There are many sizes of mandrels, and my preferences are for the 3/32" (2.4mm) and the 1/8" (3.2mm) sizes. I have smaller and larger ones, but these are absolutely the ones I use the most. Note that when you get new mandrels, you will need to wash them off and hold the ends over your torch flame to make sure that no oils are on them, as that can prevent the bead release from holding properly, causing it to flake off into your glass or possibly causing the bead to permanently adhere to the metal. As for bead release, I started with the Devardi release that came with my kit and then bought two more bottles of it after that. It works decently, but can be a bit of a pain to clean out of the beads later. I tried Dip-n-Go Sludge Ultra on a whim when it was on sale at one point and I, honestly, can say it is life changing. I love this stuff. I have not ever had it flake, I have not had a stuck bead since using it, and it cleans out of the holes very easily. This is now my go-to bead release. And yes, you do need to clean the beads later. Some people use a dremel or other fancy tools, I just have the simple set listed on the right and a stiff pipe cleaner and it does the trick for me. |

|

Other Tools

A handheld marver is a must for me. Mine is an aluminum one from Devardi, but they also come in graphite. You will hold a tool like this in one hand while you roll the bead across the surface to smooth or flatten it.

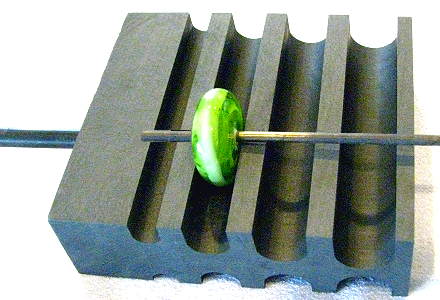

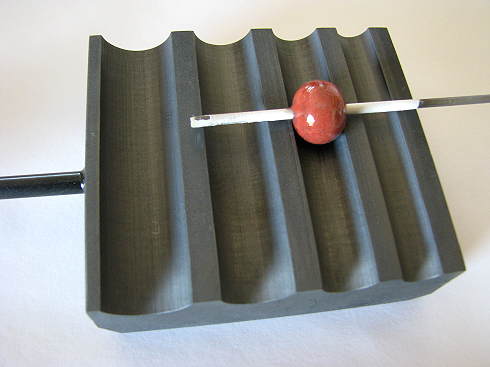

Other marvers have shaped surfaces that allow you to consistently make beads of a certain size or shape. I have a dozen of these and my favorites can be seen below. You do not need these to start out, as a simple marver paddle and gravity can make beads of many shapes and sizes, the shaped marvers just allow you to do it a bit quicker and more consistently.

One other tool that I absolutely cannot live without is an antique brass knife. Stahl knives are wonderful for working glass. Aside from my marving paddle this is the item I reach for the most. You can find them on ebay and sometimes on Lampwork destashing forums. I only paid $15 for mine and it is very much worth it. Many of them are quite decorative with horn or ceramic handles. I cannot recommend owning one enough. Hot glass does not like to stick to brass, so you can use this tool to press designs into your work, mash small areas flat, spread encasing glass... the list goes on.

A Wandering Elf participates in the Amazon Associates program and a small commission is earned on qualifying purchases.

RSS Feed

RSS Feed