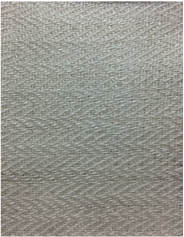

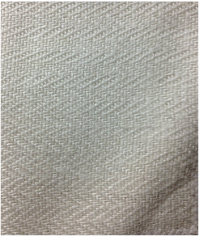

Linen fabric still on the loom.

Linen fabric still on the loom. Historically, once the weaving of linen fabric was completed, a coarse piece of linen might be beaten to make it more soft or a fine textile might have been pressed flat to close up the gaps between the threads and give the surface a pleasant sheen. (Bond 175-181) Even in modern times linen fabric can undergo this finishing process called mangling. Mangling uses weight and sometimes moisture (and modernly, heat) to flatten the yarn and create a smooth, polished surface on the fabric.

Photo credit - Walters Gallery Archives

Photo credit - Walters Gallery Archives Note that while many of these stones appear black, they are actually dark very green glass. They were pressed, domed side down to the fabric, and pushed in a back and forth motion to flatten and polish the fibers of linen textiles. (Walton 1776)

At Pennsic 41 I had Historical Glassworks craft a dark green glass smoothing stone for me, so that I could experiment with the technique myself.

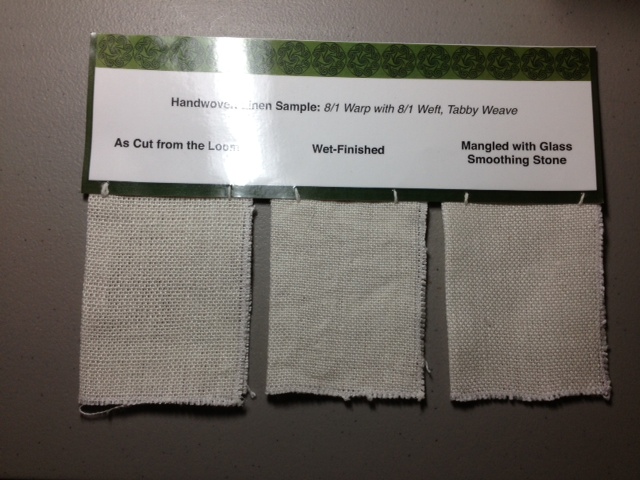

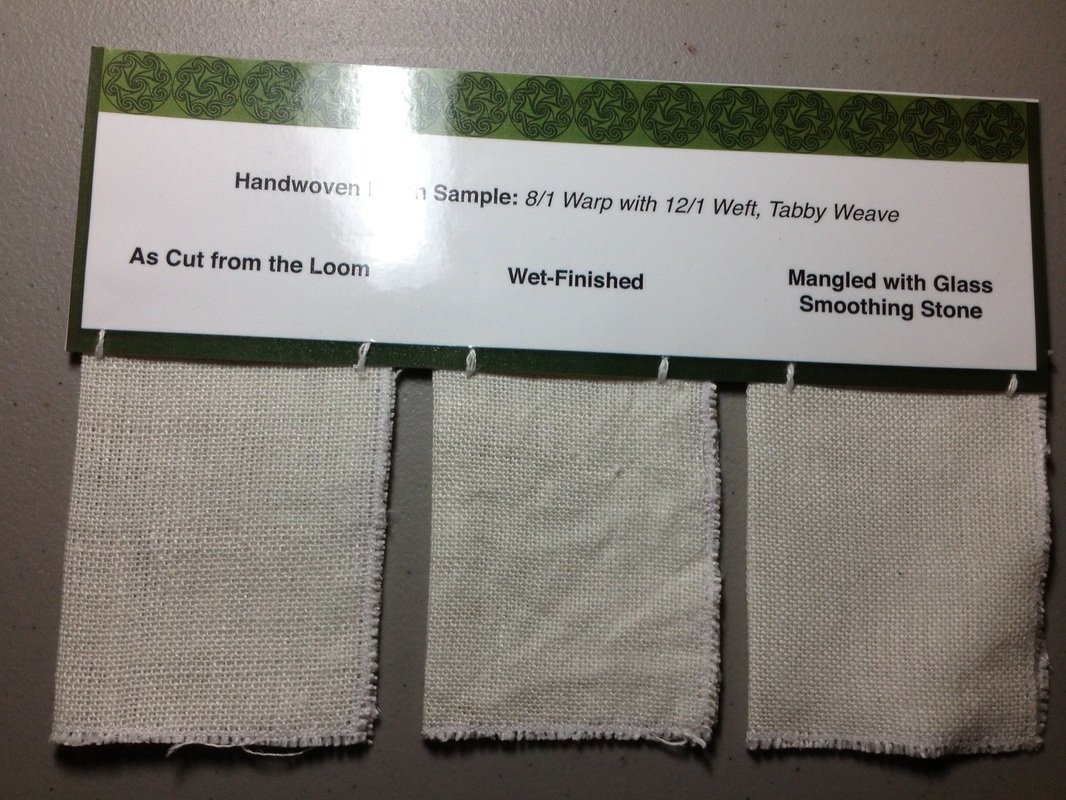

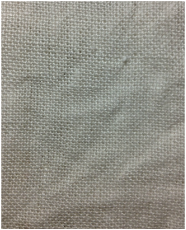

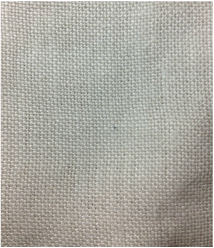

When I cut the fabric from the loom, I took each of my different weaves and cut them into three pieces. The first was left as it was on the loom (which means it still had my boiled flaxseed sizing on it), the second was washed and allowed to dry and the last was washed and mangled.

My first attempts to mangle were on dry fabric. This resulted in the linen fibers fuzzing up to some extent. I tried again after dampening the fabric, pressing most of the water out and then mangling it. While the gaps in the weave closed somewhat with the wet-finishing the final act of pressing the textile with the smoothing stone created a soft, flat surface that has a bit of sheen to it.

Ejstrud, Bo, Andresen, Stina, Appel, Amanda, Gjerlevsen, Sara and Thomsen, Birgit. “Experiments with flax at the Ribe Viking Centre” (Ribe Viking Centre & University of Southern Denmark), 2001.

Bond, J.M. and Hunter, J.R. “Flax-growing in Orkney from the Norse Period to the 18th Century,” Proc. Soc. Antiq. Scot. 1987. 175-181.

Walton, P. "Textile Production at 16-22 Coppergate." The Archaeology of York Volume 17: The Small Finds. 1977.

RSS Feed

RSS Feed